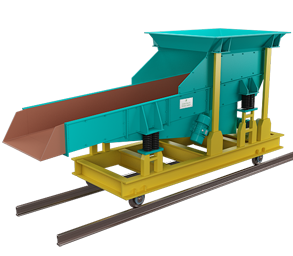

Vibratory Furnace Charger

The metallic components like scrap, bales, pig iron and foundry retains are stored in the hopper. The hopper shape is specially designed to enable bulky and irregular scrap pieces to be extracted without problem.

Main Advantages Of Vibratory Furnace Charger

- Extremely controlled feed of material into the vibratory furnace charger

- Very fast as compared to manual of vibratory furnace charger

- Minimum heat loss of the vibratory furnace charger

- No direct exposure of manpower to the vibratory furnace charger

- Prevents damage to the vibratory furnace charger lining

Tell us your buy requirements or Call +91 9940083567 / 9380521567

The metallic components like scrap, bales, pig iron and foundry retains are stored in the hopper. The hopper shape is specially designed to enable bulky and irregular scrap pieces to be extracted without problem. Vibratory furnace charger is effective solutions to problems such as high labour cost, hazards operators faced in foundries, melting shops etc. Such a kind of automation allows foundry men to work at a safe distance thus preventing injuries arising out of molten metal splash. It also facilitates in rapid and quick charging of the vibratory furnace charger thereby allowing maximum utilization of the vibratory furnace charger, in addition to this, the damage to furnace lining is avoided which normally occurs in manual charging of the vibratory furnaces.

Vibratory Furnace Charger consists of a vibrating feeder mounted on a moving trolley with a storage hopper mounted above the feeder. Our company makes vibratory furnace charger which basically comprise of the following parts. Vibrating Feeder suitable for delivering required capacity. Storage hopper of required capacity, Moving carriage with driving arrangement. Control panel for operating the system. Cable reeling Drum / Cable Drag Chain.

The vibratory charging car on the vibratory furnace charger comprises a discharge chute with vibratory feeder for the metallic components and is hopper mounted on the travelling framework with drive gear. The discharge snout is inclined and formed of a rounded trough to bring about a good charger distribution and enable irregular or bulky pieces of scrap or returns to be discharged. The feeder is driven by unbalanced motors. The vibration frequency can be altered by an A. C. Inverter, thereby regulating the feed velocity and also influencing the noise emission. The batch hopper as well as the charging feeder is built in sandwich construction which reduces the noise generated by contact between the charger materials and the hopper walls or feeder deck. However, this does not eliminate the noise produced by contact between the charger pieces themselves.

The required amount of scrap metal is loaded into the storage hopper at the loading point. The trolley then carries the vibrating feeder along with the storage hopper to the vibratory furnace charger point. Here, the vibrating feeder is energized and the material is effectively discharged into the vibratory furnace as per the required capacity. As the metal is melted down, fresh batch of metal can be fed into the vibratory furnace charger thereby keeping the vibratory furnace charger full. The capacity of the vibrating feeder can be varied by varying the amplitude of variations. The amplitude of vibrations can be varied by adjusting the position of centrifugal weights or by using a variable frequency drive (optional). A control panel specially designed to suit individual client requirement depending on the sequence of operations required is provided.

Star Trace vibratory furnace charger feeders and charger systems give you precise automated batch control, optional scrap drying and other charger enhancement capabilities. Equally important, automated systems help improve worker safety. Charger nose piece is designed specifically for your vibratory furnace charger to control fumes and direct the charger into the center of your vibratory furnace charger. Vibratory furnace charger systems can be motorized to move forward, backward, up, down, or transversely. In special applications, vibratory furnace charger feeders can be fully radio controlled and independent of rails.

- Very fast as compared to manual charging of vibratory furnace charger thereby enabling optimum use of the melting system.

- Extremely controlled charging of material into the vibratory furnace charger.

- Prevents damage to the vibratory furnace charger lining since the material is properly guided into the vibratory furnace charger so as to avoid the material from hitting the furnace walls.

- No direct exposure of manpower to the vibratory furnace thereby preventing dangerous accidents due to metal splash (since the operator can carry out the operations at a very safe distance).

- Minimum heat loss of the vibratory furnace since the charging process can be maintained continuously at the required rate.

The demand for high quality foundry products and their cost effective production places high demands for vibratory furnace charging equipment in melting plants. Though much of the initial head way made in foundry automation was with the mold making process, more important is the melt shop automation. This includes remote vibratory furnace charging systems. Automation is mainly thought of as a solution to high labour cost and it certainly can increase workers productivity. However, much more important today is the effect of automation on quality. Another important advantage that automation provides in foundry environment is enhanced safety. For example automation allows foundry men to work at a safe distance from molten metal or do their jobs behind protective barriers thus reducing injuries from metal splash or furnace eruption. Also where automation exercises monitoring & control functions, it helps prevent accidents related to in-attention or judgement errors.

Manual charging also directly exposes melt deck workers to the dangers of metal splash from charger materials hitting the molten bath and of vibratory furnace charger eruption or explosion caused by wet or damp charger materials. Metal splash is one of the most common melt deck hazards & ideally, melt deck worker should be away from the furnace or behind protective barriers during charging which can only be accomplished with remote systems. Remote charging systems enhance safety not only by allowing melt deck worker to be away from the furnace during charging, but by reducing the chances of damage to the vibratory furnace charger lining & the likelihood of bridging situation.

This technique brings about a greater accuracy of dispensing. The metallic components are dosed either into a weigh hopper or directly into the charger bucket which stands on load cells or by lifting magnet on crane hook with digital weigh scale.

Once the charger is prepared it is put into the storage hopper of the travelling charger. The vibratory furnace drives from the loading point onto the vibratory furnace platform in front of the induction vibratory furnace. The vibratory furnace hood is arranged in such a way that it can be fitted for charging pouring. The vibratory furnace lid itself hangs from a chain inside the hood. The hood is raised and the charging machine drives up to the charging point and than the vibrating feeder is energised, The vibratory furnace charger is filled and as the contents are melted down the furnace charger is kept full.

Various logic circuits can be designed depending on the customers requirements so as to charger multiple furnaces using a single vibratory furnace charging device.The system can also be designed so as to achieve a completely automatic cycle with time lags provided for energising and de-energising the vibrating feeder and also for providing time lag for the reversing cycle.

- Patented charger feeder nosepiece expands to prevent jams, fits tight to vibratory furnace hood to contain fumes and any potential splashback, and directs charge into center of vibratory furnace to reduce vibratory furnace damage.

- Noise reduction vibrating feeder troughs for quiet loading and unloading.

- Heavy duty vibratory feeder designed for 24/7, 365 operation with little maintenance requirements reduces your planned downtime.

- Two-mass, natural frequency charger feeder design requires very little energy to operate, reducing your energy costs.

- Variable speed material discharge.

Leading in sales we have a renowned place in the industry. Many manufacturers Suppliers and exporters are using our equipment globally. Our excellent sales record is attributed to quality and durability which is much expected by any manufacturer in any industry. Our head quarters is in Chennai, Tamilnadu, India which can be directly contacted for sales enquiry or to any of the branch offices located through out India.