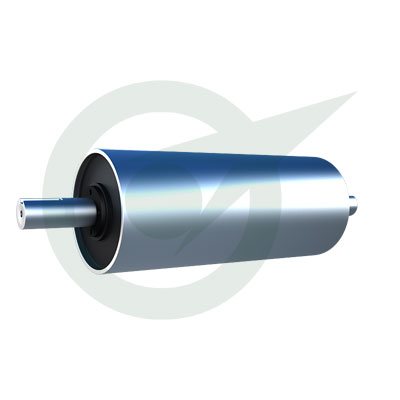

Magnetic Tail Pulley

Magnetic Pulley also known as the magnetic tail pulley is one of the basic methods of separation for removing ferrous material which may either be contaminants or metals to be separated for further processing. Magnetic Tail pulley is usually fixed at the tail of the conveyor and thus they gain their name "Magnetic Tail Pulley". It is a common procedure to install a magnetic pulley at the beginning or at the tail to facilitate separation. They are attached to the conveyor system in the tail end and perform as effective tool in magnetic separation.

Tell us your buy requirements or Call +91 9940083567 / 9380521567

The magnetic tail pulley is simple in construction and works with efficiency. It consist of an outer covering made of SS 304, a 360 degree strong permanent magnet and an axis for rotation. The whole setup is built to withstand the wear and tare it is subjected due to continuous operation.

The working of magnetic Tail Pulley is facilitated by it being wrapped by a conveyor belt and movement initiated by motor. Once the power source is switched on with the motor functioning the tail pulley starts rotating. The substance to be subjected for separation is fed on the conveyor and when they enter the magnetic field separation is achieved. Ferrous and non ferrous material are collected in separate collection areas.

- 360 degree rare earth magnet magnet

- Strong magnetic field that permeates through feeds in the tail end of the conveyor

- Conveyor belt facilitates in effective separation.

- Choice of rare earth Neodymium or Strontium Ferrite permanent magnet available.

- Removable shafts for easy handling.

- Paper Industry

- E-Waste Processing

- Cement

- Waste recycling

- Recovery from garbage

- Carbon and quarts cleaning

Magnetic Tail Pulley is available in different sizes and dimensions to fulfill the need of varied clients in different industries. With changing technology the models of magnetic tail pulley have been upgraded accordingly.