Magnetic Drum Separator

Star Trace Ltd India is an exporter, manufacturer & supplier concerning magnetic drum separator & various other equipment which utilize the magnetic property pertaining to magnets

Main Features Of Magnetic Drum Separator

- Low maintenance

- High volume throughputs

- Robust design

- Different magnet configurations

Tell us your buy requirements or Call +91 9940083567 / 9380521567

Star Trace Ltd India is an exporter, manufacturer & supplier concerning magnetic drum separator & various other equipment which utilize the magnetic property pertaining magnets. Permanent drum design magnetic separator ensures purity of end product, metal extraction that have sale value and preventing other machinery from damage. As manufacturers, suppliers & exporters we design magnetic roll separator along single, double & triple drum. Multiple drum design was introduced matching all manufacturers, suppliers & exporters who need magnetic separation towards improved sale. It has been a proven technique to use permanent magnet design drum facilitating removal regarding ferrous impurities.

Magnetic drum separator Feeder designPlace from where the feed is introduced has vibratory motion making even spreading possible.

Magnetic drumThough the drum attracts iron particles, it does not have magnetic properties. A semicircular permanent magnet lodged within the drum radiates magnetic field. Half drum area exhibits magnetic field & remaining half does not. Electro magnets may be used on sale request relating client's specification. Manufacturers & suppliers dealing other products also use the drum design facilitating smooth functioning. Exporters give due priority towards drum numbers.

Collection:Collecting, iron as well as non ferrous material happens at collection point in two separate places. The drum attracts towards itself ferrous feed & non ferrous deflects towards another area. Drum number varies in different sale; depending on number of times refining is needed. When fine clarified output is needed by manufacturers, drums number up to three, customizing drum number & design may vary towards satisfying all sale parameters.

- Highest grades of magnetic material including Neodymium-Iron-Boron (rare earth), Samarium-Cobalt (rare earth), Ceramic and Alnico.

- Dust tight 304 stainless steel housing construction.

- 1/4" x 2" x 2" angle iron inlet and outlet flanges.

- Access door for inspection and maintenance.

- Adjustable feed gate to meter product flow.

- Adjustable magnet positioning for optimum separation.

- Continuous cleaning discharges ferrous contaminants separation from product flow.

- Inlet has a fixed diverter to direct product flow over magnet.

- Outlet has splitter for ferrous and non-ferrous product discharge.

- Chemical

- Pharmaceutical

- Refractory

- Separator for native mineral

- Foundry

- Sand processing

- Waste recovery

With professional manufacturers, suppliers and exporters at your service; manufacturing magnetic drum separator design matching standards available is to make a sale. Our engineers have expertise; catering all needs relating magnetic drum separator with permanent or electro magnet. Send a request citing specification in design, number of drums pertaining permanent magnetic drum separator & our executives will suggest solutions & help finalizing sale.

The permanent magnetic drum separator is used in mines and coal separating factories to separate fine highly magnetic substances or remove the highly magnetic substances from the non-magnetic materials.

The magnetic drum separator has three types of tanks:- Half Counter current Tank (CTB)

- Direct Flow Tank (CTS)

- Counter current Tank (CTN)

which are used according to different granular and technological requirements.

The features of our products are: optimized computer design, rational magnetic circuit, strong magnetic coercive force and high-remanence permanent magnet which can keep the magnet's performance for a long period and safe guard the long-term interest of the customers, which makes the whole structure reliable.

The following are the features of Magnetic drum separator:

- Low maintenance & High volume throughputs.

- Minimal spare parts required & Robust design.

- Drum housing can be designed to suit space limitations.

- Wide range of Drum diameters and widths available.

- Available in Single / double and triple drum complete unit.

- Different magnet configurations available suited to individual needs.

- Enhanced separation compared to equipment such as Magnetic Pulleys.

- Magnetic Drum Separator is supplied with fixing blocks and Shaft for adjustment.

- Powerful magnetic zone approximately of 135 Deg fixed inside rotating SS Drum.

- Complete Magnetic Drum Separator machine is supplied with hopper, vibrating feeding tray and gear/motor assembly.

- Electro Magnetic drum Separator is made using Aluminium or Copper conductors.

- Made with Strontium ferrite magnets & Automatic self cleaning mechanism.

The totally enclosed type drum comes complete with a chute type feeder, hopper, adjustable feed regulation gate, magnetic drum and geared motor drive in a ready for use condition. Inlet and Outlet openings are flanged for ease of connection to customers duck work. Double or Triple totally enclosed machines can also be supplied if required by clients.

Wet Drum Separator:STAR TRACE's Wet Permanent Magnetic Drum Separator is offered in size of dia 1200mm(48') and 916mm(36'W) ion lengths of upto 3000mm(10'). Three basic magnetic drum separator designs are available for copping, roughing and finishing/cleaning applications. Each type can be supplied in single drum or multiple drum stages of taconite or magnetic and also for recovery of magnetic medium in dense media plants. The stationery magnet yoke is an assembly of Rare Earth Neodymium Permanent Magnets. The rotating drum is available with optional rubber or stainless covers. The magnetic flux pattern will match the tank configuration for optimum performance.

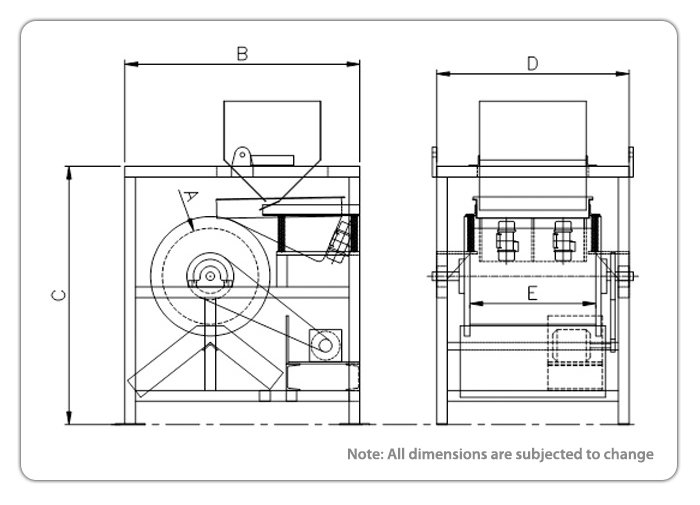

| Technical Specification | ||||

| Drum Diameter "A" in mm |

Drum Width "B" in mm |

C | D | E |

| 300 | 200 | 950 | 1060 | 500 |

| 300 | 950 | 1060 | 600 | |

| 350 | 950 | 1060 | 650 | |

| 400 | 950 | 1060 | 700 | |

| 450 | 950 | 1060 | 750 | |

| 500 | 950 | 1060 | 800 | |

| 600 | 950 | 1060 | 900 | |

| 750 | 950 | 1060 | 1050 | |

| 900 | 950 | 1060 | 1200 | |

| 1050 | 950 | 1060 | 1350 | |

| 1200 | 950 | 1060 | 1500 | |

| 375 | 300 | 1025 | 1135 | 600 |

| 350 | 1025 | 1135 | 650 | |

| 400 | 1025 | 1135 | 700 | |

| 450 | 1025 | 1135 | 750 | |

| 500 | 1025 | 1135 | 800 | |

| 600 | 1025 | 1135 | 900 | |

| 750 | 1025 | 1135 | 1050 | |

| 900 | 1025 | 1135 | 1200 | |

| 1050 | 1025 | 1135 | 1350 | |

| 1200 | 1025 | 1135 | 1500 | |

| 450 | 300 | 1100 | 1210 | 600 |

| 350 | 1100 | 1210 | 650 | |

| 400 | 1100 | 1210 | 700 | |

| 450 | 1100 | 1210 | 750 | |

| 500 | 1100 | 1210 | 800 | |

| 600 | 1100 | 1210 | 900 | |

| 750 | 1100 | 1210 | 1050 | |

| 900 | 1100 | 1210 | 1200 | |

| 1050 | 1100 | 1210 | 1350 | |

| 1200 | 1100 | 1210 | 1500 | |

| 600 | 450 | 1250 | 1360 | 750 |

| 500 | 1250 | 1360 | 800 | |

| 600 | 1250 | 1360 | 900 | |

| 750 | 1250 | 1360 | 1050 | |

| 900 | 1250 | 1360 | 1200 | |

| 1050 | 1250 | 1360 | 1350 | |

| 1200 | 1250 | 1360 | 1500 | |