Liquid Line Separators

Liquid Line Magnetic Separators- The Liquid Line Magnetic Separators is a specially designed compact Inline magnetic separator for removing tramp iron from liquid stream. Very fine particles may be mixed up in the production line which may be due to wear and tare faced by the stainless steel pipeline. It is usual that they collect and even go unnoticed by electronic metal detector. In this dangerous situation liquid line magnetic separators plays a very important role. When inline magnetic separators or Liquid Line Magnetic Separators are fixed in the pipeline of flowing liquid it will trap all the ferrous fragments thus purifying the liquid. The liquids may be anything from water to sauce consistency. Though differences in density have an impact on performance of inline magnetic separators or Liquid Line Magnetic Separator, variations in model and specification takes care of it to serve as effective traps.

Tell us your buy requirements or Call +91 9940083567 / 9380521567

Star Trace stationed at Chennai, Tamilnadu, India has been in the business for many years and have developed innumerable products that have undergone continuous up-gradation to match the changing trends in liquid line / inline magnetic separation. Being one among the few top rated manufacturers, suppliers and exporters of Inline magnetic separators we have our technology in place to sustain our leading position in sales.

The Liquid Line Magnetic Separators are also referred by the following names Liquid Line Separators/ Inline Magnetic Separators and liquid line magnetic traps. The construction and working of Liquid Line Magnetic Separator is very simple but efficiency is followed strictly.

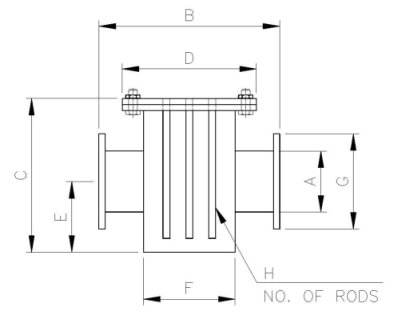

Construction / Parts of Liquid Line Magnetic Separators

The Inline magnetic separator consists of a top lid on which the magnetic trap are mounted, the pipeline is attached at one end and after refining, it comes out of the outlet pipe as refined & contamination free product. The magnetic traps in Liquid Line Magnetic Separator are rod like structures that have magnetic activity due to the rare earth magnet fitted inside. Once considerable amount of traps have been done in the liquid line / inline magnetic separator the lid can be unscrewed and cleaned manually. The position of liquid line magnetic separator can be either horizontal, vertically or even at a slope. None of these positions affect the activity of magnet in the liquid line / inline separator.

Parts of the inline magnetic separator that need a special mention

- Body made of 100% SS.

- Perfect fitting tight screws, no possibility of leakage.

- Can be easily accessed and checked how many ever times needed.

- Tri-clamp, bevel seat, welded inlet and outlet.

- Rare earth magnet of diameter one inch.

- SS 304 and 316 type available.

- Water proof magnets.

Cage Style "T" Traps:

These T trap Liquid Line Magnetic Separators are designed for large volume and semi liquid line flow. Once traps are done in the liquid stream they settle to the rear end of the tube of the Liquid Line Magnetic Separator, so they are safe from being washed out. When unscrewed for washing complete removal is possible.

Plate Style "T" Traps:

Viscous and fibrous consistency material use plate traps. It works on the same principle as above and is very effective. It can be fixed in pipeline with varying slants.

Before taking up a sale of Liquid Line Magnetic Separator check for all the requirements else you could have a discussion with our sales executives to take an informed decision.

| CAGE STYLE | |||||||||||||

| ALL DIMENSION ARE IN INCHES | Litres/Min |

||||||||||||

| Part No | A | B | C | D | E | F | G | H | Group1 | Group 2 | Group 3 | Group 4 | Weight Kg |

| STR 02 | 2 | 10 | 6 | 7.5 | 3.25 | 7.5 | -9 | 5 | 546 | 382 | 191 | 82 | 13.2 |

| STR 02.5 | 2.5 | 12 | 7.5 | 9.75 | 4.38 | 9.75 | 0 | 7 | 909 | 638 | 318 | 136 | 22.7 |

| STR 03 | 3 | 12 | 9 | 9.75 | 4.38 | 9.75 | 0 | 7 | 909 | 636 | 318 | 136 | 22.7 |

| STR 04 | 4 | 12 | 12 | 10.25 | 4.38 | 9.75 | 0 | 7 | 1227 | 859 | 432 | 186 | 27.2 |

| STR 06 | 6 | 23 | 18 | 16 | 13.38 | 10.75 | 11 | 9 | 7273 | 5091 | 2545 | 1236 | 104.4 |

| STR 08 | 8 | 26 | 24 | 19 | 17.25 | 12.75 | 13.5 | 9 | 7273 | 5091 | 2545 | 1236 | 124.7 |

| STR 10 | 10 | 30 | 30 | 23.5 | 21 | 16 | 16 | 15 | 7273 | 5091 | 2545 | 1236 | 261 |

| STR 12 | 12 | 34 | 36 | 25 | 21 | 18 | 19 | 15 | 14318 | 10023 | 500 | 2432 | 295 |

| STR 14 | 14 | 36 | 42 | 27.5 | 23.38 | 20 | 21 | 15 | 14371 | 10023 | 500 | 2432 | 333.5 |

| STR 16 | 16 | 40 | 46 | 32 | 25.63 | 24 | 23.5 | 17 | 23836 | 18545 | 8273 | 4000 | 442.4 |

| STR 18 | 18 | 40 | 50 | 32 | 27.5 | 24 | 25 | 17 | 23836 | 16545 | 8273 | 4000 | 476.4 |

| PLATE STYLE | |||||||||

| Model no. | A | B | C | D | Group1 | Group 2 | Group 3 | Group 4 | Weight Kg |

| STR-15 | 1.5" | 4.25" | 5.50" | 10.0" | 245 | 189 | 94 | 57 | 8 |

| STR-20 | 2.0" | 4.25" | 5.50" | 10.0" | 245 | 189 | 94 | 57 | 8 |

| STR-25 | 2.5" | 4.75" | 7.75" | 13.5" | 528 | 339 | 226 | 132 | 14 |

| STR-30 | 3.0" | 4.75" | 7.75" | 13.5" | 528 | 339 | 226 | 132 | 14 |

- Technical data specification subject to change.

- Special Liquid line separators can be made on request, Please send us your technical data and application, required for our engineers to provide.

Many different sizes are on sales and any sales closing with deviation from available dimension will take extra days, which may vary from time to time. We being the leading manufacturers, suppliers and exporters in Chennai, Tamilnadu, India as well as globally have a good stock of all equipments. Star trace has carved an unique place of its own in sales among all manufacturers, suppliers & exporters. As we are from Chennai, Tamilnadu, India all our products are made locally matching global standards.